Analytics Unleashes Focus, Speed, and Downtime Reduction

This company was dealing with the same challenge almost every mid-market manufacturer is facing: How do we increase the chance of machine up-time and prioritize the right maintenance actions that will have the biggest impact?

Together, we drove the implementation of a technology-driven preventive maintenance program that is world-class for the industry. Communications are faster. Maintenance is more effective. And, downtime is, well, down. In just one month, overall downtime dropped by 16% while their leading cause of downtime dropped by nearly 38%.

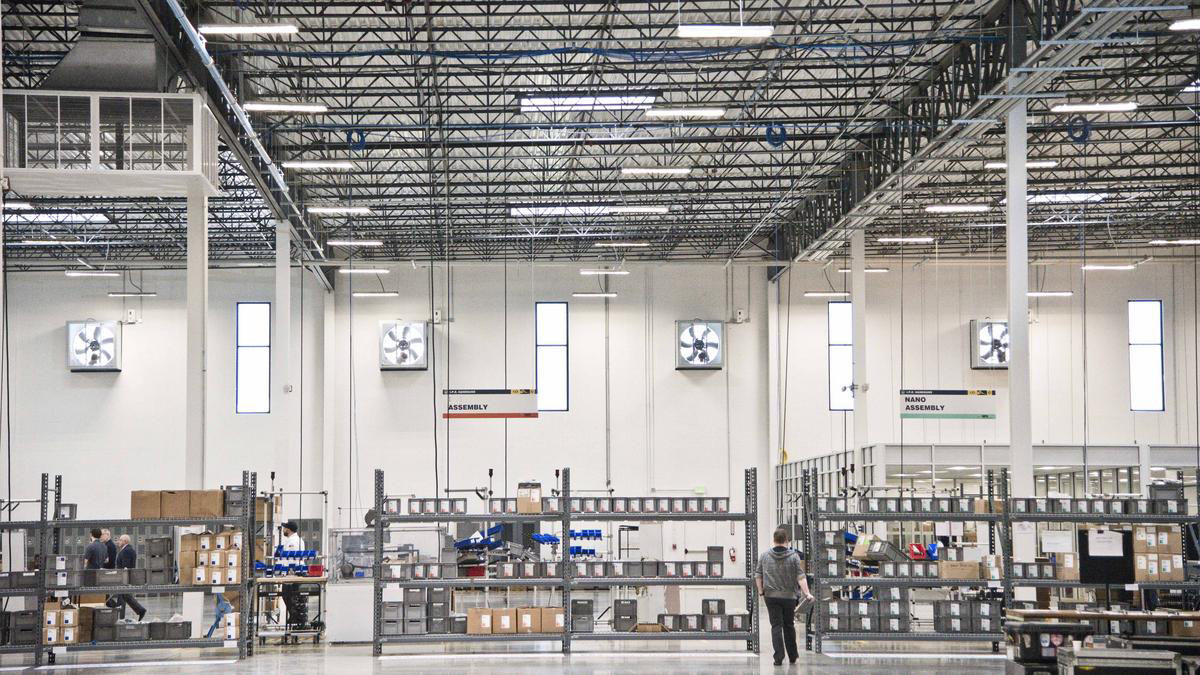

Overview

-

Company Overview

- 20+ Production Lines

- 100+ Machines/Assets

- 500+ unique SKUs

- 15,000+ Products Behind Schedule

-

Assessing the Landscape

- Challenge: Produce ~12,000 products per month

- Avg. 5-8 Production Lines Down every day (roughly 25%)

- Aging machinery with significant unplanned downtime

-

Identifying Opportunity

-

- Four maintenance technicians (1-3 years experience each)

- Solve drivers of machine downtime (constant competing priorities)

- Understand downtime root causes

- Setup preventive maintenance program

- Reduce burden on maintenance team

-

Results

(within the first month of implementation)

16% reduction

Total Downtime

38%

reduction

Area 1 Downtime

$240K

annualized

savings

Cost of Downtime

The Solution

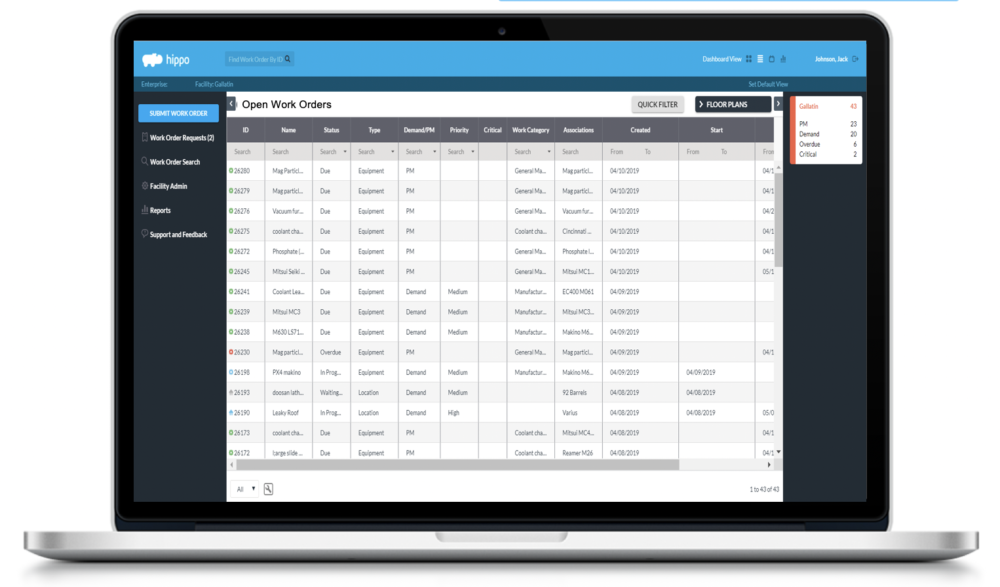

Machine Downtime Dashboard

We didn’t do anything miraculous. We simply allowed this company's leaders to leverage all the data and information their programs and machines were already collecting. We made it visible. We translated it into knowledge the company's leaders could use to make better decisions and drive action.

Preventative Maintenance Program

"We had been trying to put a preventive maintenance program in place for over a year. AMEND helped us do it in less than one month."

- Former Sr. Director of Operations

The AMEND Process

Setup Process

In order to understand downtime, you need to track it.

Create Tools

A team cannot reach its potential until it has the right tools to succeed.

Take Action

We stand side-by-side to ensure roll-outs are successful and sustainable.